Mastic

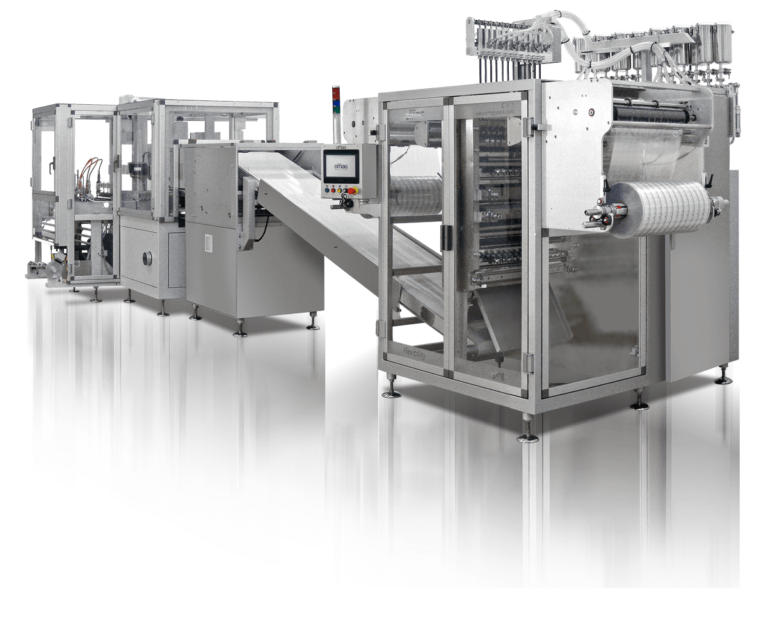

Foulad Machine Delijan Co.

Mastic is a product that is used for sealing. Having high flexibility and the ability to install on various surfaces such as wood, aluminum, glass, marble, etc., as well as high resistance to heat, heat and humidity are special features of mastics.

Types of mastics

There are different types of mastics, and they are divided into different types in terms of ingredients, such as bituminous mastic or bitumen-based mastic, epoxy mastic, silicone mastic, acrylic mastic, polysulfide mastic, and polyurethane mastic.

Mastics are divided into two types, cold mastics and warm mastics, depending on the type of implementation and the desired quality and performance. This issue is related to the mastic temperature during execution. Bitumen-based mastic or bitumen-based mastic or bitumen-based sealing mastic also has two types, hot and cold, each of which is used in its own places.

Cold bituminous mastic: It is a type of elastic sealant based on bitumen rubber. This mastic dries naturally and has high resistance to heat and weather conditions. This type of mastic based on bitumen can be used in all vertical and horizontal seams. Cold bitumen mastic is used for concrete seals of concrete sidewalks, bridges, roofs and asphalt. This type of mastic based on bitumen is also used to fill the gaps between different buildings on the roofs.

This type of mastic can withstand temperatures between minus five degrees Celsius and plus seventy degrees Celsius. Also, if it is in contact with sea water, there will be no problem.

Hot bituminous mastic: It is a type of elastic sealant based on bitumen rubber and is used for executive and expansion joints. It is used in such a way that it is heated until it becomes completely smooth and flowing, and then it is used to cover executive seams. The maximum allowable temperature of mastic based on hot bitumen is 190 degrees Celsius. The difference between this mastic and cold type mastic is their resistance. Mastic based on hot bitumen, because it is applied in heat and high temperature, it has more resistance after application than its cold type. It has very high flexibility and adheres well to various concrete, wooden and iron surfaces.

Advantages of mastic

On the surfaces where mastic has been used, we will have a smooth, soft and polished surface, and from the quality aspect, there is no need for putty. Due to their sealing properties, mastics can be used in external spaces such as the roof or yard, as well as in parts of the building that have high or low temperatures (such as cooler channels or heater channels).

In mastics, the presence of materials that prevent the harm and damage of the ultraviolet rays of the sun has made it very appropriate to use mastics on the roof that is exposed to direct sunlight.

The lack of corrosion on metals has caused mastics to be used as the only type that does not cause this problem in metals. Also, due to the flexibility of mastics, it is very appropriate to use them in joints and parts that may vibrate and move.

Disadvantages of mastic

It is not suitable to use mastics in joints that have a lot of movement and are too long. Mastics perform their task well only when there is constant pressure on them. But the movements should not be constant. Also, in order for the mastic to work well, it must be applied in a completely thick layer in the desired place, and if the layer is thin, the result will not be good.