Aluminum foil - Izogam foil

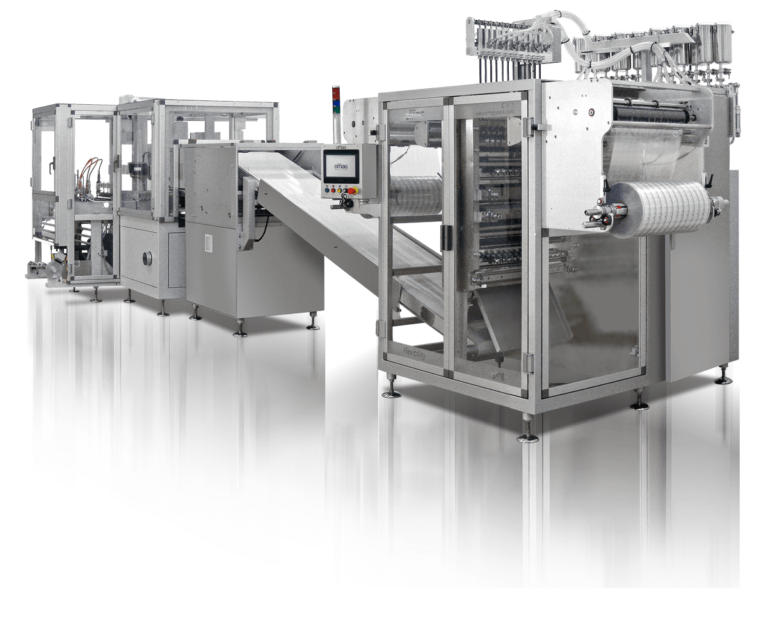

Foulad Machine Delijan Co.

One of the most important layers used in the production of Izogam is aluminum foil, which has a specific thickness and width and is easily formed. These sheets prevent bitumen from liquefying due to sunlight reflection.

Izogam foil application

The use of standard aluminum foils in the production of Izogam increases the endurance and durability of Izogam and insulation against the decomposability of the constituent components and prevents the wear and corrosion of Izogam. It also increases the resistance of Izogam against acid rains and increases the useful life of Izogam due to its high flexibility.

Standard Izogam foil

- High thickness is the most important feature of Isogam foil, which should be between 14 and 16 microns.

- The width of the foil when performing the isogam to cover the entire surface of the isogam should be 95 cm.

- The weight of each roll of Isogam foil should be 200 to 280 kg.