Tissue

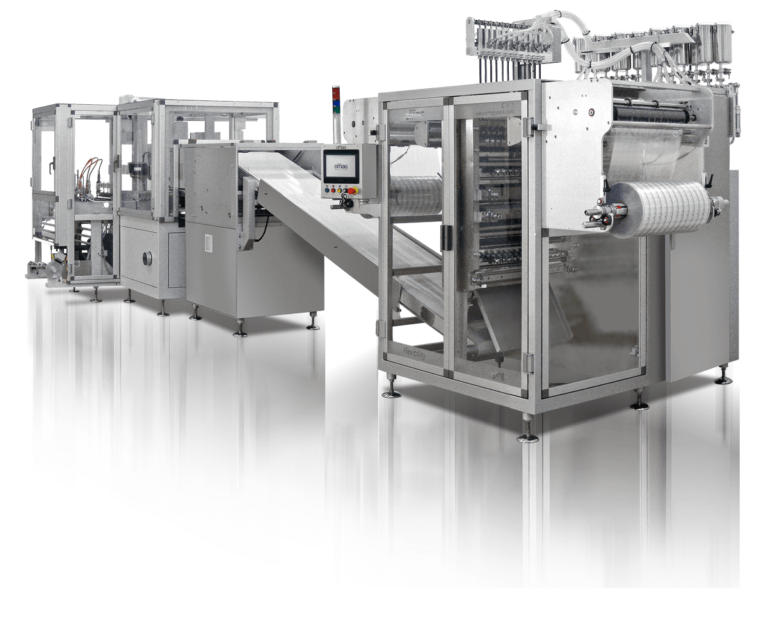

Foulad machine Delijan co.

According to the type and quality requested for production, the Izogam product has different layers, the task of each of which is to add a special function and property to the Izogam for specific and different performance purposes.

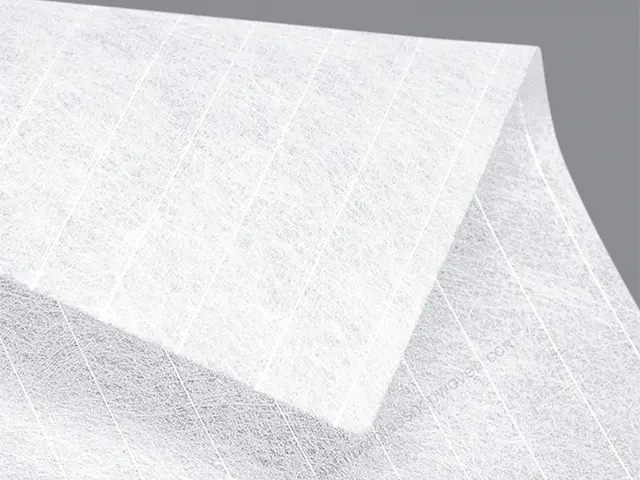

One of the important layers used in Izogam is the tissue layer, the tissue is usually placed in two layers in the Izogam compound. The first layer is made of polyester and it is used to increase the resistance of Izogam and create a stable structure for Izogam against longitudinal and transverse tension and the second layer of Izogam tissue is made of mineral glass fibers (it is necessary to explain that depending on the type of Izogam and the application that will be defined for it, these layers may also have differences).

The tissue is actually a felt made of mineral glass fibers, this felt is usually reinforced with glass threads. Glass fiber adhesive is phenolic resins, melamine or polyvinyl acetate with urea formaldehyde.

The quality of the type of fibers and materials used as adhesives and of course the reinforcing threads increases the tensile strength of these felts.

Glass fiber felt standards (tissue)

1- The tissue must be produced according to the specifications of the standard 3891 of the National Standard Organization.

2- The produced tissue must have a uniform surface and thickness.

3- A tissue with a minimum longitudinal tensile strength of 15 kg per 50 mm and a minimum transverse tensile strength of 2 kg per 50 mm and a weight of 50 grams is standard. For example, if a tissue with 66 threads and a weight of 50 grams is produced, this product is the tensile strength does not pass the production standards.

4- The fiber felt should be impregnated with chemicals (resin) and be uniform after the heating stage.

5- The mass measuring device detects the amount of tissue surface as 20 grams per square meter.

6- On the outer surface of the tissue, there should not be any mineral glass shards or glass pellets.

7- The minimum distance of reinforcing threads (glass threads) should be 15 mm.

8- When opening the rolls in Izogam production companies, the tissue should not be damp and its layers should not stick together.

9- The edges of the flat should be smooth and without any folds