Design and construction of industrial production lines

Foulad Machine Delijan

The most basic part of any economic plan is to examine parameters such as the goal and desire of the investor, familiarity with the production process and the type of raw materials and products, and to examine the existing standards, to examine the location of the project and to be aware of the rate of the fixed and current costs of the project and the amount of investment in the plan by the investor, in the next steps, by analyzing the available data, possible proposals will be presented in the form of a schedule of project implementation with a work breakdown structure by the technical and engineering team of Foulad Mashin Delijan in terms of the combination of machinery and the type of production line implementation.

Choosing the type of operation and production of products from the mentioned production line (according to the customer’s request, the type of available raw materials, the amount of investment, etc.) …

- How to run the production line (choosing machines considering the type of operation, the amount of customer investment, etc.)

- The location of the factory establishment (taking into account standard criteria and trustee organizations, access to the consumer market, access to raw materials, capacity and type of operation).

- How to design the factory and implement the infrastructure (how to implement a factory considering the standards of the national standards organization and the production process and international standards, the type of operation and production capacity, the required infrastructure according to the type of production line and operation and …).

- Financial calculations and estimates (costs of running a production line, taking into account the justified capacity and the type of machines determined and the equipment required for production, construction and infrastructure costs of a factory, current and fixed costs, etc.).

- Gantt chart and project phasing (project management based on prerequisites and requirements, prioritization based on technical and engineering principles and experience of past projects, presentation of Gantt chart, determination of executor and supervisor, etc.).

The stages of design to start-up of the industrial and production factory are detailed as follows:

1-Providing feasibility studies and preparing the economic justification plan required for economic and initial estimates to start a manufacturing company in the field of producing various products.

2-Selection of production technology according to investment conditions, environmental needs assessment and feasibility assessment

3-Line design and arrangement of devices (Lay out)

4-Designing the required space and buildings such as production halls, warehouses, offices, facilities and areas in accordance with GMP conditions and ISO standards

5- Suggestion of machines and table of advantages, disadvantages and features, technical specifications and prices of machines regarding the desired project

6- Monitoring the installation of machinery and equipment based on location and layout design

7- Equipping and designing the relevant laboratory and providing the method of equipping and designing the relevant laboratory and providing test methods

8- Examining and proposing different production lines based on different brands and different production capacities, different manufacturing countries, in compliance with the highest degree of related standards

9- Supplying machinery and equipment or accompanying the applicant to choose the best machinery and equipment from the sources provided and monitoring their supply

10_ Providing all engineering services for designing and selecting equipment, purchasing engineering, monitoring and inspecting the process of manufacturing equipment, installing and setting up the production line

11_ Optimizing the production capacity until reaching the nominal capacity

12_ Engineering consulting in the field of training and transfer of production technology, choosing materials and fixing product defects and reducing the percentage of production waste.

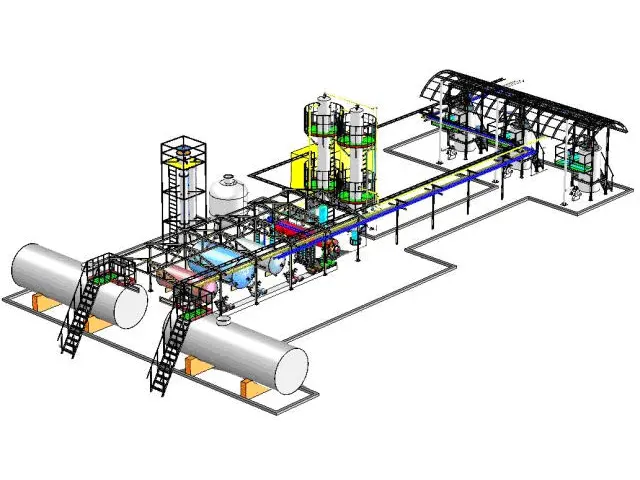

Implementation of factory infrastructure and technical site design

Factory set-up infrastructure includes all the steps during which the necessary grounds are provided to run a production line. The infrastructure required to set up the factory is done in the form of four stages of setting up the engine room, setting up the main infrastructure of the production hall, machinery requirements and implementing septic sewage. The technical and engineering team of Foulad Machin Delijan company, simultaneously with the production of machinery in the factory, by sending the technical team to the project site, takes the necessary measures to implement the infrastructure of the production line.

- Providing construction plans and maps, mechanical, electrical, facilities, treatment plants, architecture, etc. in accordance with international rules and standards and the production process

- Implementation of the foundations of sheds and administrative departments and facilities and…

- Implementation of the shed

- Monitoring the implementation of the work according to the customer’s request and relevant standards to the organizations in charge and…

- Implementation of the engine room

- Running a morgue

- Implementation of septic tank and treatment plant

- Implementation of the scale

- Implementation of the infrastructure required for the production line (electrical panels, trays, water, wind and steam piping, generator)