Spunband technology

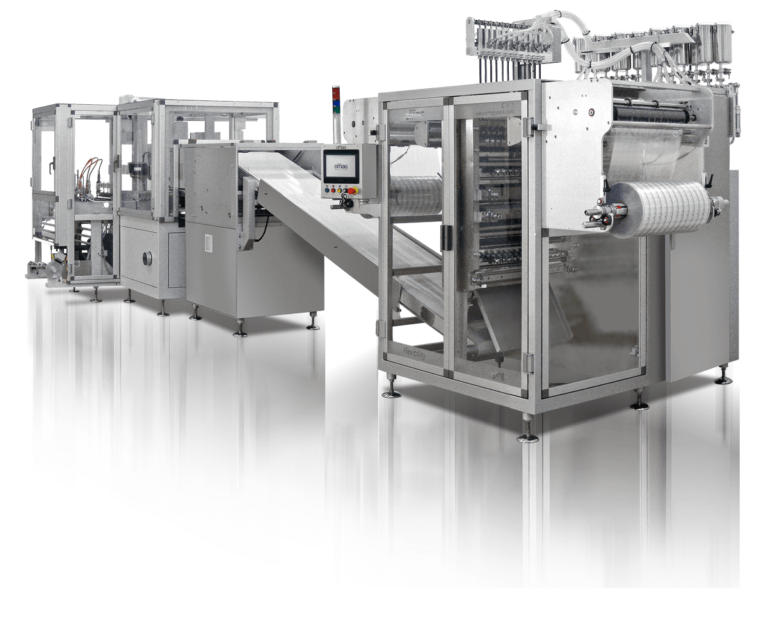

Foulad Machine Delijan Co

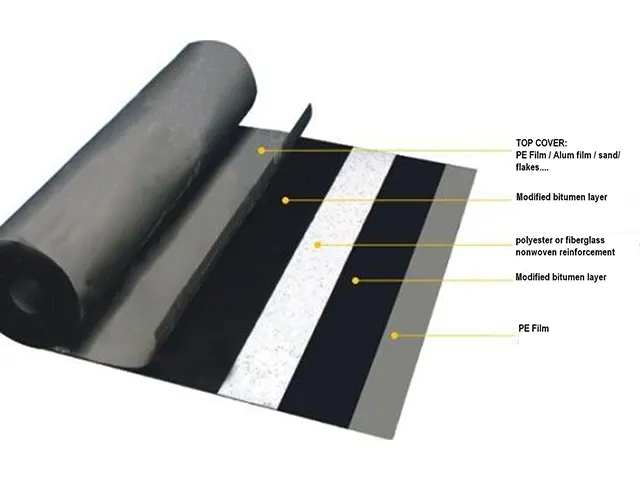

Spun bond Spun bond is a layer of Non-Woven fabric. This product is produced through processes and with mechanical and chemical factors (resins) under special thermal conditions. Spanband is one of the best and strongest materials known for its light weight and extraordinary flexibility, which has many applications.

If this material has a low density, it is used for one-time use in the medical, health, cellulose industries, and if it has a higher density, it is used in industries such as automobile manufacturing, insulation (heat-moisture), etc. .

In the production of waterproofing, spunbond is used as a strong layer with very high tensile strength and strength, which multiplies the life of isogam.

Types of spunbond

In the production of spunbond, depending on its raw materials, two types of spunbond PET and PP are produced. The difference between spunbond PET and PP (polypropylene) is its resistance to gamma rays.

Characteristics of PET spunbond

- It has the ability to be dyed and has a very high adhesive property during execution.

- Very high resistance against water and solvent absorption

- High thermal resistance that causes dimensional stability at high temperatures. PET spunbond is resistant to gamma rays

- flexibility at low temperatures – high resistance at high temperatures

- Excellent resistance against stretching and tearing (longitudinal and transverse)

- Impressive resistance to delamination, puncture after installation, impact, as well as high resistance to chemicals

- Very high adhesion and colorability

- The ability to absorb all kinds of nano solutions, including: fireproof, antibacterial, etc.

- being affordable and economical and having a lower cost compared to waterproofing with tissue – polyester layer

- It has a very light weight and does not impose much additional load on the building.

- Possibility of insulating sloping roofs with Isogam Spunbond and not loosening due to high heat