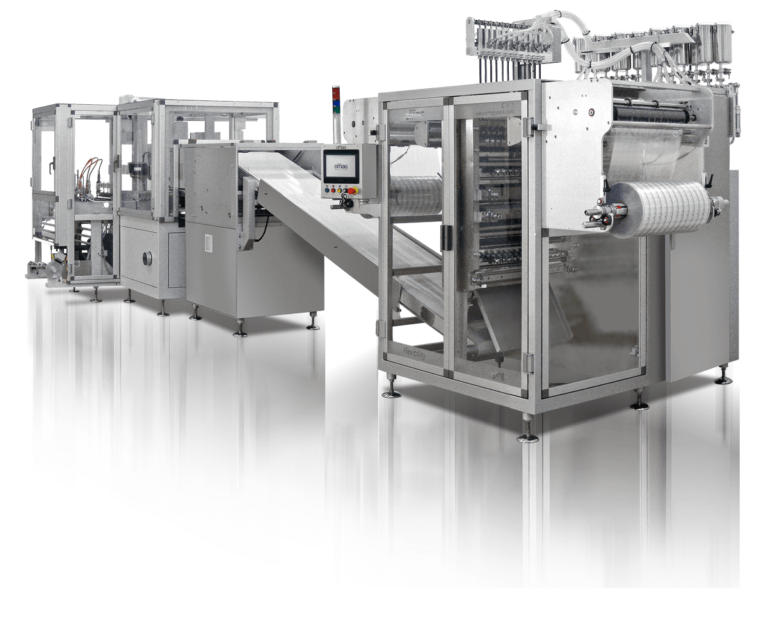

Installation of industrial production lines

Foulad Machine Delijan

One of the active groups in Delijan Machine Steel Company is the technical and engineering group of the company, which, by taking advantage of domestic and foreign expertise and experience in many fields, builds, installs and operates new factories and production lines and develops previous production is working, ready to cooperate and provide services to respected craftsmen.

The start-up of the production line is done in the third executive phase of the factory and after the completion of the implementation phases of the facilities and the construction of machinery. The machines of the production line are placed in the right place according to the location maps and are started after connecting to the required pipes and facilities. This engineering group manages and implements all the stages of the work in a completely engineering manner, taking into account the technical and safety requirements of installation and operation, such as installation conditions, as well as pressure, temperature, etc. In the project control unit and for management during the implementation of this company, it uses the relevant experts to control the project and performs the activities through the project control management system.

Basic and standard installation and commissioning of machines for monotonic production and non-stopping in the production line process is one of the basic and strategic rules of the company’s technical and engineering group; which, in the continuation of the installation and start-up stages, has institutionalized this importance in the production programs of the target company with proper training of the personnel of the production company, and along with the correct implementation of production plans, while reducing the production time, the production costs are also reduced and the profit margin increases.

At the last stage of installation and commissioning, the trial production of products is carried out, in such a way that the product desired by the customer is produced on a trial basis and based on the initially agreed amount for trial production, so as to ensure the correct operation of the production line, the quality of the product is also measured according to the standard formulations.

Operational and executive affairs related to installation and personnel training:

- 1- Dispatch of company engineers and specialists to install, operate and maintain machines.

- 2- Teaching correct work methods and machine maintenance principles to employees and machine operators.

- 3-Providing technical assistance and support on an ongoing basis and conducting periodical inspections of the factory.

- 4-Helping and training employees to prepare a periodic schedule of preventive inspections, fix technical problems and continuously monitor the performance of machinery.